| TANK TYPE | Horizontal Cylindrical |

| PROJECT CODE | AD- Merkblatter / EN 13445 |

| DESIGN TEMPERATURES | Min -20°C / max +70°C |

| DESIGN PRESSURE | 17,5 bar |

| TEST PRESSURE | 26,5 bar |

| MATERIAL | P355 GH or P355NH |

| HEAD TYPE | Elipsoidal |

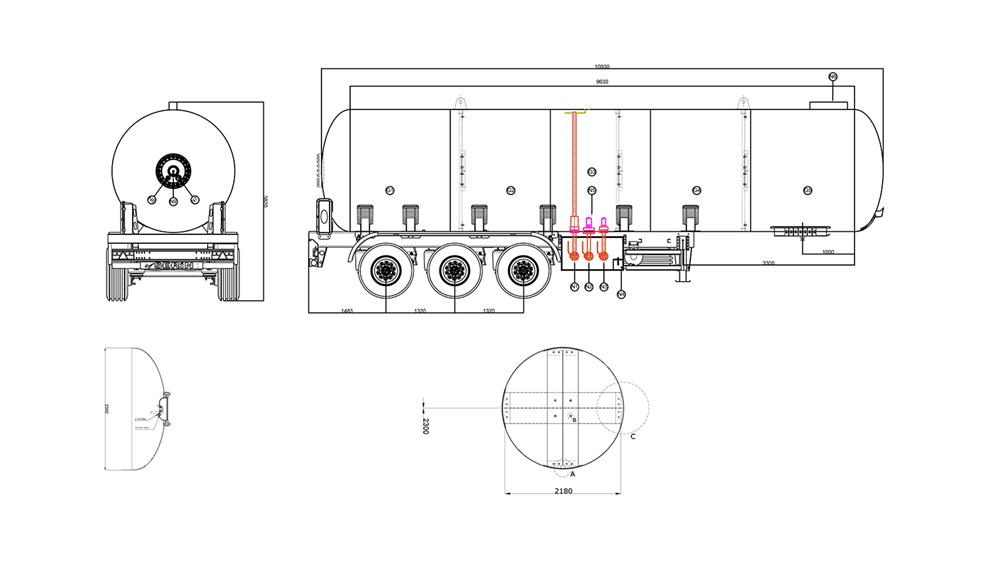

| TANK OUT DIAMETER | 45 m3 2.400 mm |

| TANK BODY THICKNESS | 45 m3 10 mm |

| TANK DOMED THICKNESS | 45 m3 12 mm |

| TOTAL TANK LENGTH | 45 m3 11.200 mm |

| CORROSION | 1 mm |

| TANK VOLUME | 45 m3 |

| TANK EQUIPMENT | Hydraulic Operator 1 Piece, 2″ Ball Valve 2 Piece BATU, 2” Hydraulic Valves 1 Piece ATILIM, 3” Hydraulic Valves 1 Piece ATILIM, 2″ Safety Valves 2 Piece ATILIM, Rotogauge (Rotary Level Indicator) 1 Piece, ATILIM Glycerin Manometer ( 0-25 bar), Ø 63 1 piece, PAKKENS Thermometer (-30 / 60 °C) Ø63 1 piece, PAKKENS Acme Filling Cap 2 pieces ATILIM Menhole 1 piece 16” Filter 1 piece |

| SANDBLASTING AND PAINTING | Before painting, Tank SA 2.5 quality primer and polyurethane based white top coat total min. 150 microns. COLOR: WHITE |

| CONTROL (INSPECTION AND TESTS) | All tests and inspections mentioned below will be carried out under third party control and certified by the same authority. Control and approval of design and calculations, Material inspection and separate stamp transfer, Visual and dimensional inspection plate orientation, Head control, Radiographic control, Penetration paint test, Hydrostatic test, A/M tests and inspection reports will be presented to the customer. The customer will be issued inspection certificates for the tank and the tank, which will be issued by the third party upon completion of the inspections. |

| CERTIFICATION | ISO 9001-2008 VE EN 3834-2 |

| WELDING METHOD | All welders are certified according to EN 287-1:2004 standard. Full penetration will be ensured in welding seams. Welding will be done by welders as submerged arc welding. The grooves shall comply with EN ISO 9692-2. & Filling Material to EN ISO 14171 and Flux to EN 760. |

| COMPARTMENTS | The tank will have 3 anti-liquefaction compartments. |

| CHASSIS | The semi-chassis is made of 6252 material. Steel quality. HEAVY DUTY type |

| AXLE | Brand: Local Axle 12 TON. Capacity: 3X12 tons/Axle Type: Air Suspension Axle Drum brake |

| SUSPENSION SYSTEM | Air Suspension |

| FREN SİSTEMİ | WABCO EBS |

| LANDING GEAR | OMS brand Double Speed, 24,000 lifting capacity, Mechanical Parking Legs |

| TIRES | Size 385 X 65 X 22.5 European Brand 6 pieces. |

| BALL VALVE CABINET | RIGHT SIDE |

| MUDGUARD | Aluminum plated steel fenders |

| KINGPIN | 2″ flanged and high pressure stress and rupture resistant steel and bolted OMS brand that can be disassembled and easily replaced. King Pin plate thickness will be 12 mm and will be reinforced with min. 3+2 steel 160 NPU. |

| ELECTRICAL SYSTEM | There are 24 V electrical systems in European standards. There will also be electric lights and warning signs on the tank top and trailer top. (ADR). 2 stop lights on the Rear Bumper, 5 stop lights on each side of the tank. |

| REFLECTORS | 3M Brand yellow color reflector on both sides of the tank and 3M Brand red color reflector on the rear bumper and rear camber. |

| ACCESSORIES | 1 Steel Bumper, 1 water tank (30 lt capacity made of Plastic), 1 basket type spare wheel carrier, 2 chocks and connections, 2 Fire Extinguishing Cabinets (ADR), 2 Food & Tool cabinets made of Steel, A sunshade will be installed on the tank. |